Welcome to Labkafe ~ Orientallabs Retail Services Private Limited

Jul 23, 2021 / By Soumen Mondal / in Learning Experiments Physics

Aim:

To measure (a) diameter of a given wire (b) thickness of a given sheet and (c) volume of an irregular lamina using screw gauge.

Apparatus:

Theory:

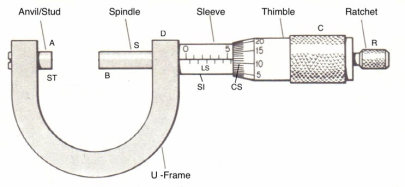

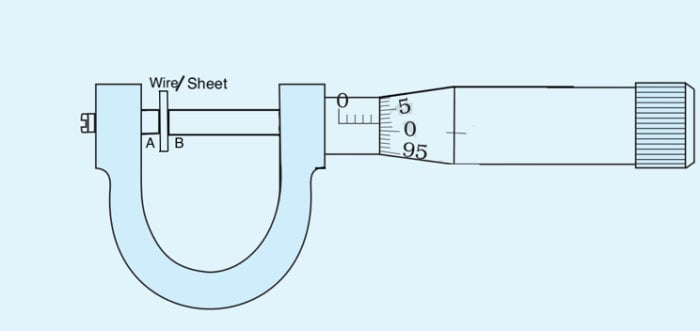

Using Vernier Callipers we can measure length accurately up to 0.1 mm. To measure more accurately, up to 0.01 mm or 0.005 mm, we use screw gauge. A Screw Gauge is an instrument of higher precision than a Vernier Callipers. In any ordinary screw, there are threads and the separation between any two consecutive threads is the same. The distance advanced by the screw when it makes its one complete rotation is the separation between two consecutive threads. This distance is called the Pitch (p) of the screw. It is usually 1 mm or 0.5 mm. Fig. 2.1 shows a screw gauge. It has a screw S which advances forward or backward as one rotates the head C through rachet R. There is a linear scale LS attached to limb D of the U frame.

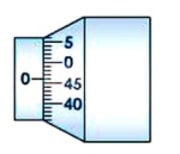

The smallest division on the linear scale is 1 mm (in one type of screw gauge). There is a circular scale CS on the head, which can be rotated. There are 50 or 100 divisions on the circular scale. When the end B of the screw touches the surface A of the stud/anvil ST, the zero marks on the main scale or pitch scale or linear scale LS and the circular scale should coincide with each other as shown in fig. 2.2.

Principle:

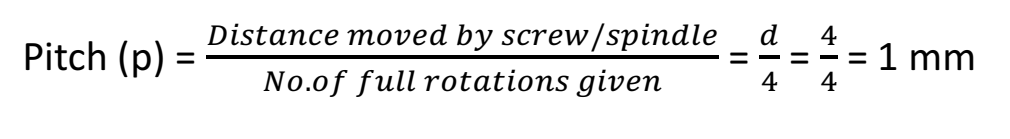

Pitch of the Screw Gauge

The linear distance covered by the tip of the screw (B) in every rotation of the circular scale is called the pitch of a screw gauge. This movement of the spindle is shown on an engraved linear millimeter scale on the sleeve. To find the pitch, give full rotation to the screw (say 4 times) and note the distance (d) advanced by the circular scale over the pitch scale.

If the distance d is 4 mm The pitch can be represented as:

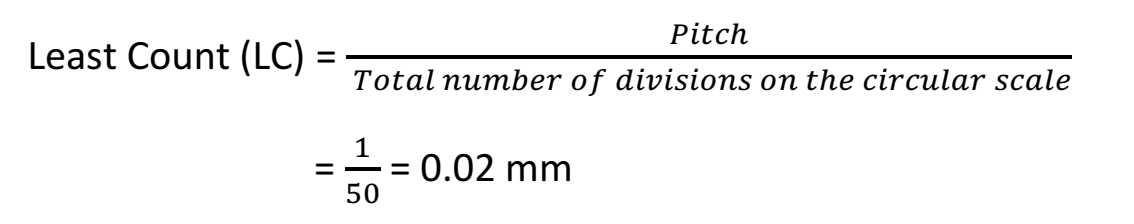

Least Count of the Screw Gauge

On the thimble there is a circular scale which is divided into 50 or 100 equal parts. We are using a screw gauge which has 50 circular divisions. The Least count (LC) is the distance moved by the tip of the screw, when the screw is turned through 1 division of the circular. The least count can be calculated using the formula;

Determination of Zero Error:

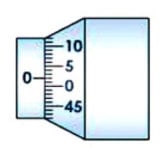

When the stud and spindle are brought in contact with each other, the zero of circular scale should coincide with reference line of main scale. In that case the screw gauge have no zero error as shown in Fig. 2.2. However, when the zero of circular scale does not coincide with reference line of main scale, the screw gauge is said to have zero error.

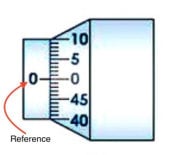

The zero error is said to be positive zero error if on bringing the spindle in contact with stud, if the zero of the circular scale lies to the bottom of the reference line as shown in Fig. 2.3. Owing to this error, the measured readings will be systematically bigger than the actual value by the same amount. Hence the error is to be subtracted from the observed readings. If on the other hand, the zero of the circular scale lies to the top of the reference line as shown in Fig.2.3, it is said to be negative

Fig. 2.2

Fig 2.3

Fig 2.4

zero error. Owing to this error, the measured readings will be systematically smaller than the actual value by the same amount. Hence the error is to be added from the observed readings.

To determine the error, bring the spindle in contact with the stud and note the reading on the linear as well as circular scale. If the linear scale reading is x and circular scale reading is n’ then zero error is given by ± (x + n’ × LC ). Zero correction (e) is always negative of zero error. In our case, as shown in the fig. 2.3, the linear scale reading is zero and the circular scale zerois 2 divisions bellow the reference. Therefore, the zero error is: -[0 + 2 × 0.02] = - 0.04 mm.

So, the Zero correction (e) is = -[-0.04] = 0.04 mm.

Hence, the Actual reading = Measured reading – (±e)

= Measured reading – (-0.04) for positive error

Procedure:

Measurement of diameter of the wire

Measurement of thickness of a given sheet

Measurement of volume of an irregular lamina

Observation:

Determination of least count:

One linear scale division, L.S.D. = ____ mm

Total number of divisions is the in circular scale, N = _______

Distance moved by the screw for 4 rotations, d = ________ mm

Pitch of the screw, p = 4/d = ____mm

Therefore, Least Count, L.C. = p/N= ____mm

Zero error or Instrumental error with the sign:

Zero error, e = ± (x + n’ × LC ) = _______mm

Table 2.1 Determination of diameter of the wire:

No of Obs. | M.S.R (M) mm | No of Circular scale division of the reference line (n) | Observed Diameter D0 = M + n × LC mm | Actual Diameter D = D0 – (± e ) mm |

1.(a) (b) |

|

|

|

|

|

|

|

| |

2.(a) (b) |

|

|

|

|

|

|

|

| |

3.(a) (b) |

|

|

|

|

|

|

|

| |

4.(a) (b) |

|

|

|

|

|

|

|

| |

5.(a) (b) |

|

|

|

|

|

|

|

|

[(a) and (b) corresponds to mutually perpendicular diameters.]

Mean actual diameter, Dw : …………………………………… (mm)

Table 2.2 Determination of thickness of a sheet:

No of Obs. | M.S.R (M) mm | No of Circular scale division of the reference line (n) | Observed Thickness T0 = M + n × LC mm | Actual Thickness T = T0 – (± e ) mm |

1. |

|

|

|

|

2. |

|

|

|

|

3. |

|

|

|

|

4. |

|

|

|

|

5. |

|

|

|

|

Mean actual thickness, Ts : …………………………………… (mm)

Table 2.3 Determination of thickness of an irregular lamina:

No of Obs. | M.S.R (M) mm | No of Circular scale division of the reference line (n) | Observed Thickness T0 = M + n × LC mm | Actual Thickness T = T0 – (± e ) mm |

1. |

|

|

|

|

2. |

|

|

|

|

3. |

|

|

|

|

4. |

|

|

|

|

5. |

|

|

|

|

Mean actual thickness, TL : …………………………………… (mm)

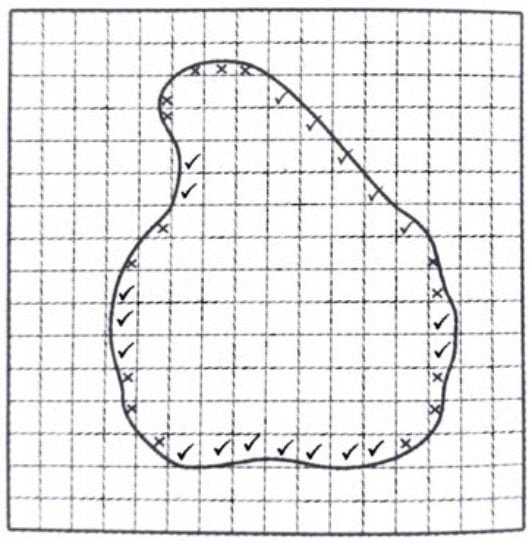

Calculation:

Number of small squares enclosed by the boundary , NL = _______

Actual Thickness, TL = ___________ mm

Area of the lamina, A = NL × 1 mm2 = _________mm2

Therefore, the volume of the lamina, V = A × TL = …………………………..mm3

Precautions:

Sources of Error:

Reference:

Your may checkout our blog on HOW TO USE VERNIER CALIPER TO FIND OUT LEAST COUNT AND MEASURE DIAMETER OF SPHERICAL BODY AND BEAKER

We are a School laboratory furniture and Lab equipment manufacturer and supplier. In laboratory furniture for school, we first design the entire laboratory room keeping in mind the requirements as per affiliation CBSE Bye-Laws. Also, we take care of the complete designing and installation of laboratory furniture.

In the lab equipment section, we have a wide range of glassware, chemicals, equipment and other lab accessories. Most of them are available for order online on our website but some of them can be procured on demand.

If you have need:-

do drop a message through chat or mail us at [email protected] or call +919007218364 and we’ll get in touch with you.

Labkafe is among the most promising laboratory supplies vendors in India. We manufacture and supply lab equipment, lab furniture, lab consumables, lab glassware, lab machines and more! Not only we manufacture lab items, we export to international resellers too. We fulfill CBSE ICSE ISC IGCSE IB State board affiliation requirements for schools by providing affiliation packages to schools. Our featured products are:

Chosen by over 1200 schools, colleges, universities, research labs, government agencies and private companies to build or renovate their laboratories, Labkafe stands as your best friend when it comes to labs. We are also a registered OEM on GeM. Our clients love us because we provide the best quality of lab products, free demos, free installation, and support for ever.

Do you wish to experience excellence too? Why not contact us today at [email protected], or call 9147163562 directly ‒ we are always available to serve. You can also use the chat button in the corner to connect to one of our representatives instantly!

Feb 16, 2023 by Biswajit Sana

Jun 03, 2022 by Swarna Karmakar