There are many experiments and tests in chemistry and biotechnology where you have to observe precipitates. But the problem with them is that when they form, they generally form a suspension and you will have to wait a long time for them to settle on the bottom of the test tube you used. That’s not efficient at all! And here is where we use centrifuges ‒ to separate heavy particles from a liquid quickly.

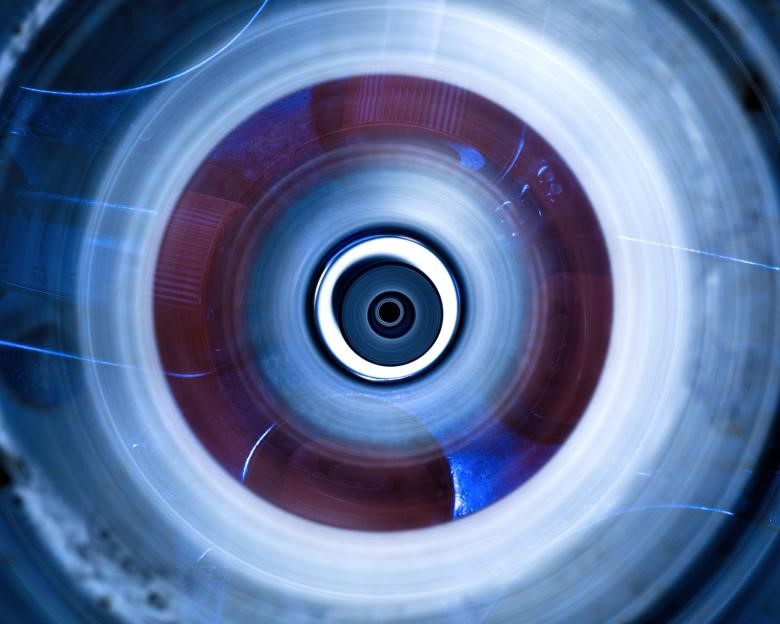

A centrifuge machine is basically a rotating platform that can hold some tube-like glassware (or plasticware) and spin them in a high velocity so that the liquid inside them presses down hard on the bottom of the tubes. If you’re looking for the definition of a centrifuge, here it is:

Definition of a Centrifuge

A centrifuge is a mechanical or electromechanical device used to separate various components of a liquid. It achieves that by simulating a very high gravity environment inside the tubes by producing centrifugal forces by spinning very fast.

The very first idea of a centrifuge came from a British military engineer named Benjamin Robins, who invented something like an arm rotating about an axis, to determine drag force on things. Later, the Prandtl brothers improved on this to make the world’s first usable centrifuge that separated cream from milk.

Description of a Centrifuge

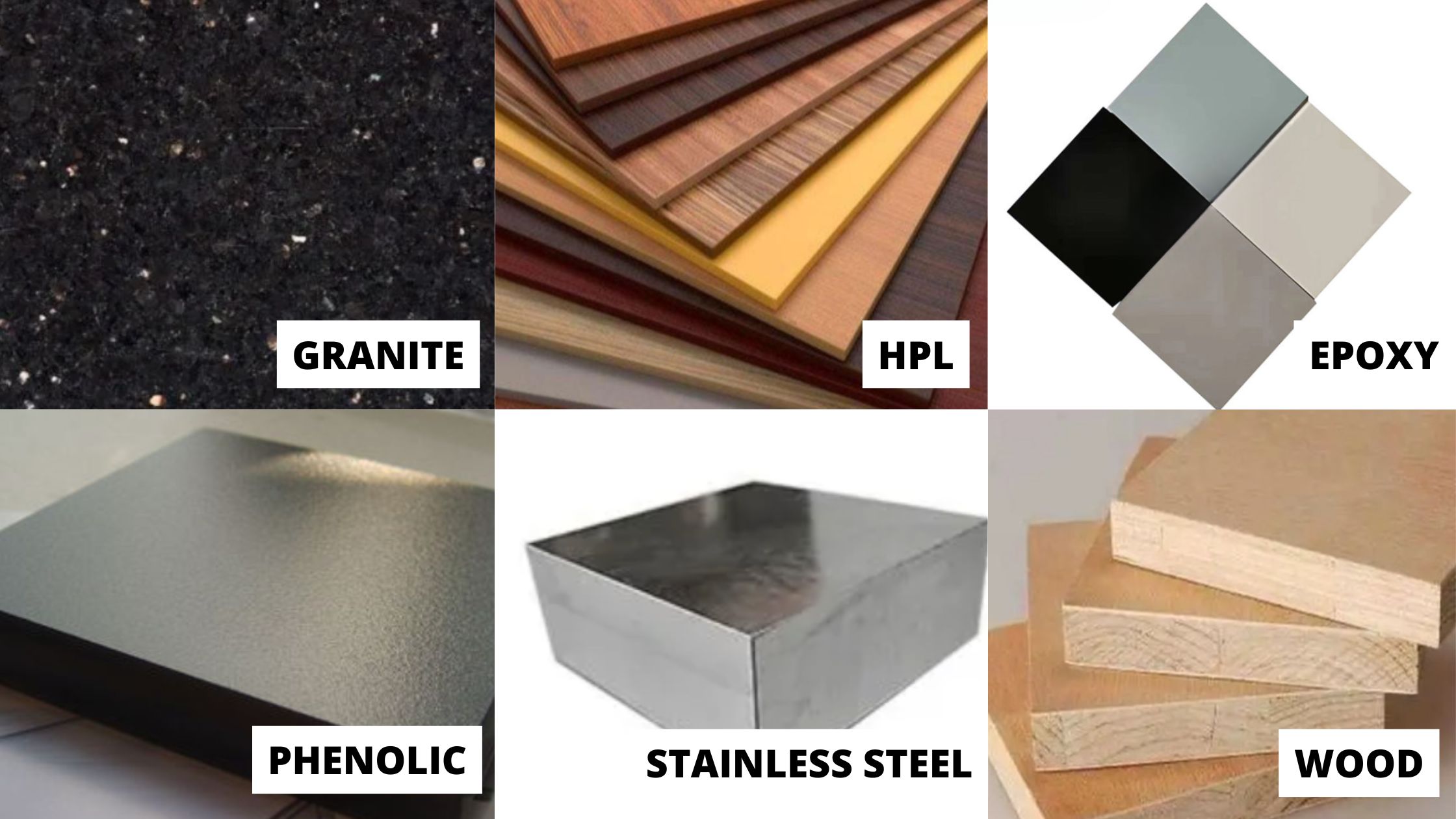

Most centrifuges you will see in the line of laboratory work are benchtop or tabletop centrifuges . It is a boxlike affair with a circular platform in it, shaped like the bottom half of a conical flask. The platform can spin very fast, and has holes drilled in it at about 45 degree angles, in which you can fit centrifuge tubes .

The box may or may not have a lid, and it will have control buttons or knobs somewhere, generally on the front. If you’re looking at a vintage or antique manual model, there may be a hand-crank instead that turns the platform through various gears.

Working Principle of a Centrifuge

A centrifuge works with the principle of sedimentation due to gravitational force. When a tube is spun with the bottom side outward to the spin, the centrifugal force created by the spin acts like high gravity on the tube’s sample. This pulls down the heavier components of a mixture faster than the lighter components ‒ and they neatly lay down at the bottom of the tubes in layers.

Continuous tubular centrifuges work a little bit differently. Instead of holding tubes, they are basically rotating drums with slanted walls. The heavy part of the mix goes to the outer wall due to centrifugal force, and the lighter part stays near the center. Both are extracted by separate outlets, while new mix gets added continuously.

How to Operate a Centrifuge

Often found in chemistry, biochemistry, and hematology labs, centrifuges are expensive lab instruments but are fairly easy to operate. All you have to do is the following:

- Place the centrifuge in its operating place, preferably a very stable lab workbench . Open the centrifuge lid. Keep the power off for now.

- Perform basic cleanup as per the manufacturer’s instructions.

- Put your liquids in centrifuge tubes (designated to fit snugly in the machine you are using) and put on the caps properly.

- Insert the tubes in the boreholes on the platform. If you have less number of tubes than there are holes (the common situation), try to distribute them evenly around the platform so that the spin can stay even.

- Close the lid and turn on the power to the device. Operate the controls to start the spin. The controls may be different from model to model, you had better consult the instruction manual first.

- If the device supports it, you may want to set a timer beforehand.

- When the spin stops (manually or automatically), let it stay still for a few minutes.

- Now collect the tubes from the platform one by one, very carefully not to shake them. Put them in a designated centrifuge tube rack .

- At the end of the workday, make sure to perform regular cleaning and maintenance for the lab centrifuge machine.

Types of Centrifuges

- Fixed-angle Centrifuges: the most common type of centrifuges you’ll find, these have a thick platform with lots of boreholes at an angle. This way, the solids have a very short distance to travel within the liquid and hit the wall of the tube very shortly, and slide down to the bottom.

- Swinging head or swing-bucket centrifuge: these have flexible holders on the rotor axis that can tilt freely. You can attach the tubes vertically, but when it spins the tubes will lift up and become horizontal. They do not normally require special tubes ‒ you can use normal test tubes in these. Some versions have their own ‘buckets’ to fit, though.

- Continuous tubular centrifuges: these weird things don’t have any place to stick a tube in. Instead, they hold the whole sample liquid within themselves that actually passes through the machine while being centrifuged! Generally found in high-volume applications.

- Decanter centrifuges: this is used to separate things that don’t really want to separate. In this application, the solid doesn’t really settle in the bottom of the tubes, but the liquid just thickens gradually.

- Benchtop or tabletop centrifuges: these are the most common, compact, fixed-angle centrifuges you can see in most laboratories. These workhorse centrifuges are relatively cheaper and you can use them in various kinds of tests.

- Gas centrifuge: yes, you can separate gasses using a centrifuge too. Though, that process is very much more complicated since gasses have a high diffusion rate and don’t really want to be separate. These are mostly used in nuclear research and application, to separate U235 and U238.

- Ultra centrifuges or ultrafuges: These are powerful centrifuges that spin insanely fast. In those, the rotor or platform assembly resides inside a vacuum compartment to eliminate air drag and can reach speeds up to 150,000 RPM. They generally have a precise temperature control system integrated as well.

- Low-speed centrifuges: not all centrifuges spin fast! Some just cruise it low and slow, making sure the sedimenting particles don’t get crushed.

- Micro centrifuges: when you want to do some really small scale separation (like pulling out the nuclei off a cell), try a microfuge. They use tubes only worth microlitres and spin at 12-13000 RPM. There are mini centrifuges as well.

- Refrigerated Centrifuges: these keep the samples very cool while it sediments. Generally found in bioscience labs.

- Blood centrifuge: though not a technical term, it may mean a hematocrit centrifuge. It uses specialized containers to work with blood samples only, showing the volume of various blood cells present in the sample.

In industrial uses, there are two basic types of centrifuge purpose ‒ filtration and sedimentation. The filtration centrifuges have a perforated wall lined with a filter medium. This lets only selected particles pass through. The sedimentation centrifuge types spin faster, generally, and the drum walls are solid.

Uses of Centrifuges

Parting the solid parts off a liquid mix is kind of an important matter in many industries, and so you’ll find centrifuges of some type in many kinds of places. The most important centrifuge uses are as follows.

- In Laboratories: Centrifuges are very common in most chemistry, biochemical, biology, and clinical laboratories around the world. They vary widely in capabilities ‒ some have heating or cooling systems in-built, some can spin at low or high speeds, some accept various sizes of tubes, some can spin flasks or beakers, etc. Pathologists do the most common type of blood tests using centrifuges, testing the sedimentation rates of various types of blood cells.

- In Dairies: in the dairy industry, they use big centrifuge machines to separate cream (fat) from milk. This is also called churning .

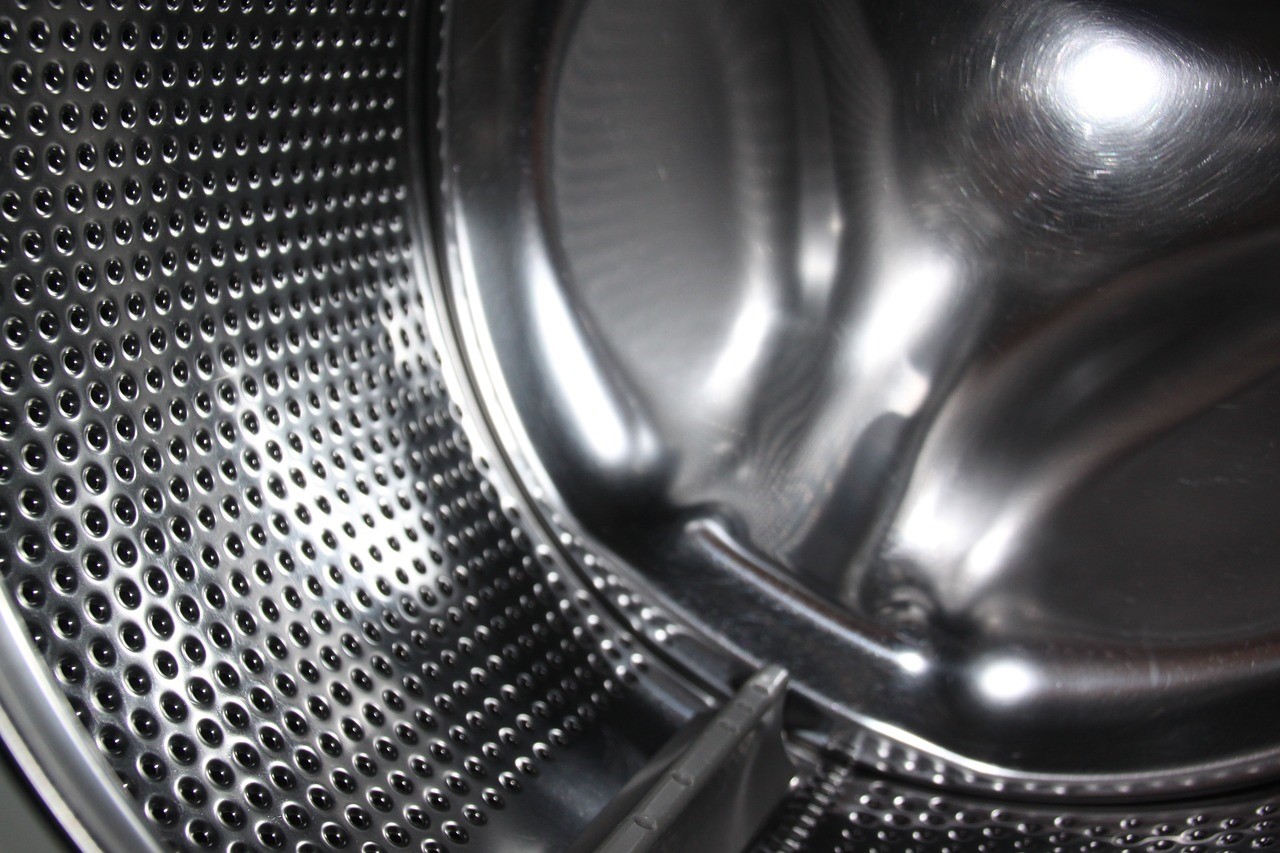

- In Homes: although not technically a centrifuge, washing machines use centrifugal force to dry clothes. The drum inside a washing machine spins very fast and the clothes stick to the inner wall of the drum, but the water gets squeezed out by the centrifugal force that’s generated by the spin.

- In water treatment: giant centrifuge machines spin the mud and sludge out of water and produce cleaner water. A similar technique is used in oil rigs to separate solid matter from freshly drilled out petroleum.

- In Aeronautics: they use big spinning wheels to simulate high gravity environments for the pilots to practice in.

- In Space and future: so far, the only way to simulate gravity out in space is to rotate a space vehicle or living capsule around an axis. No wonder most fantasy pictures of future space stations resemble gigantic wheels.

Do you want a centrifuge for your laboratory too? Labkafe has various centrifuge models to sell, as well as different sizes and types of centrifuge tubes and holders. Check them out in our lab instrument section!

Leave a Reply